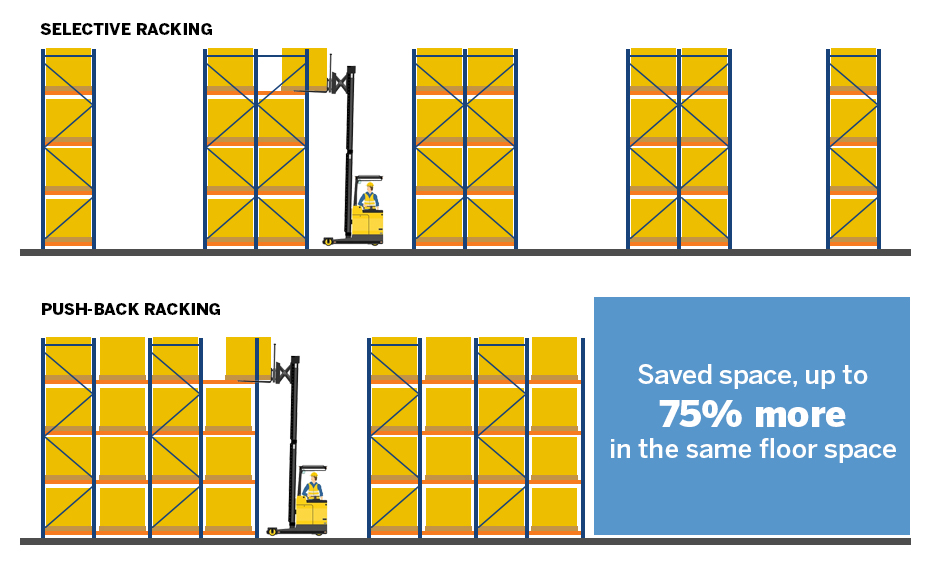

One of the biggest challenges of warehouses today is storing an ever increasing number of pallets, with an ever increasing number of products in a fixed storage space. PUSH-BACK PALLET RACK storage systems will help increase the pallet count, while offering many more pick faces than other high-density storage systems like Drive-in/Drive-thru racks.

PUSH-BACK PALLET RACK systems are a LIFO (Last-in, First-out) gravity storage system that uses inclined rails and nested carts or rollers to load/unload pallets one behind the other. This provides high-density as it only requires one aisle for picking and allows access to multiple groups of SKU’s.

.png)