The answer: whenever you want to stop wasting space, time, energy and money. Pallet flow rack systems make the most of the space in your warehouse while enhancing productivity, cutting energy costs and saving valuable time and money in warehouse worker activity. They are simple to install, come in a variety of styles, and can accommodate different size and weight of loads.

Benefits

The pallet flow system brings many advantages to the organization in terms of space, time and cost. When the focus in on quick picking, inventory accuracy and minimal movement of assets and pallets, nothing beats the pallet flow system for your warehouse. Here are five of the primary benefits:

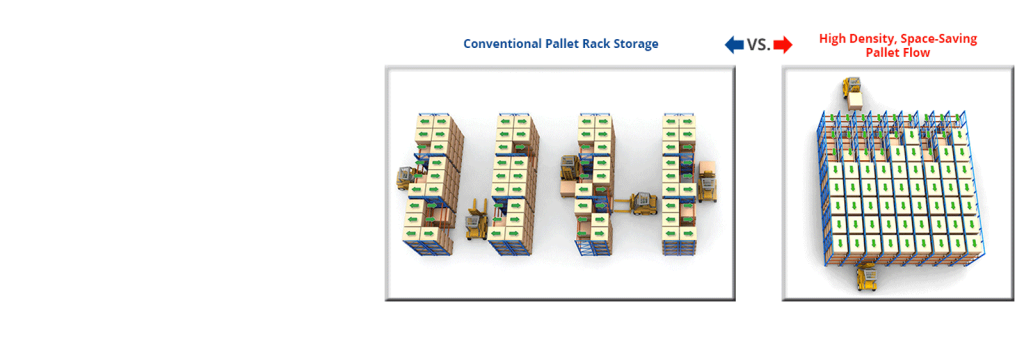

- Space Gain. Due to the configuration of wide access aisles throughout your footprint, traditional selective storage rack options waste 50-60% of your cubic space storage capability. The pallet flow system places rows of racking right next to one another, filling space and allowing material handling equipment access from either end of the row.

- Energy Savings. Use of the pallet flow rack system also conserves energy costs. The rows work based on gravity. When a pallet is pushed in on one side of the row, the rest of the pallets slide along rollers, aided by gravity, and come to rest at the other end of the row. Filling available space with product also reduces the amount of open air space to be heated or cooled, creating an energy efficient, comfortable working environment for warehouse personnel and cutting the associated costs.

- Safety. Material handling equipment can move in a consistent and prescribed pattern in the warehouse, with loading occurring at one end of the aisle, and picking or unloading occurring at the other. This minimizes forklift crossing movement and the potential for an accident. Additionally, warehouse personnel are not picking individual product, reducing the risk for injury in the process.

- Equipment Utilization. Forklifts, pallet jacks and other material handling equipment maneuver on the edges of the pallet flow system, accessing pallets and product at the ends of aisles. This allows multiple forklifts to operate in the same area but without crossing traffic, multiple aisle crossings and a defined route to loading docks and other destinations.

- Inventory Management. The pallet flow system promotes the First In, First Out (FIFO) inventory management system, ensuring that the oldest product in the warehouse is pulled first to fill orders. This places inventory in constant rotation without the need for a complex tracking system. As the oldest pallet is pulled, the rest of the pallets fall into place along the rollers, ensuring that pallets are always accessible.

There are different styles of pallet flow rack systems, some customized to particular pallet or load size, while others are general in construction to accommodate varying sizes, shapes and weights. Work with our authorized representative to find the right system for you as well as assistance in design and working within your budget.

.png)